Voting

This voting section can help you to identify the best solutions for your medical device. Please use it for creating polls and discussion both on general (e.g. use of piezoelectric sensors) and/or on specific topics (e.g. use of LM7805 voltage regulator), in order to have a more clear idea of your concept, which will be described in the next "Concept description" section.

Use of nylon velcro strap

The strap will secure the patients shoe and foot to the mechanism. The velcro strap is easy to use and has low maintenance. It has a disadvantage of being prone to wear.

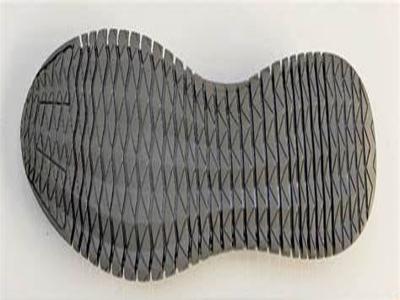

Use of rubber for sole attachment

Advantages of using rubber include comfort and durability. However it is highly prone to wear

Use of foam material for the sole attachment

The material is versatile and flexible.

Use of PVC material for sole attachment

Material adhering to the sole of the shoe should be made of PVC. Some of the advantages of using PVC are flexibility and ease of cleaning. One major disadvantage lies in the material being highly prone to heat damage.

Use of buckling as a fastening mechanism

Employs a buckling mechanism to fasten the attachment to the shoe. Ease of fastening makes it ideal for this use case. It also offers a secure and adjustable fit. Buckles may however be harder to adjust than shoe laces so may not fit well for narrow or small feet.

Use of a plastic spring

These springs are manufactured using high-performance plastic materials. Advantages include corrosion resistance, light-weight and offer greater design freedom. However they have a lower load-bearing capacity hence cannot be used in high load applications. They are also more sensitive to temperature variations than metal springs. Extreme heat or cold can affect their performance and lead to deformation or failure.

Use of a metallic spring

The metallic spring, made out of material like stainless steel, will facilitate the damping of forces by the mechanism. It is durable due to its metallic material